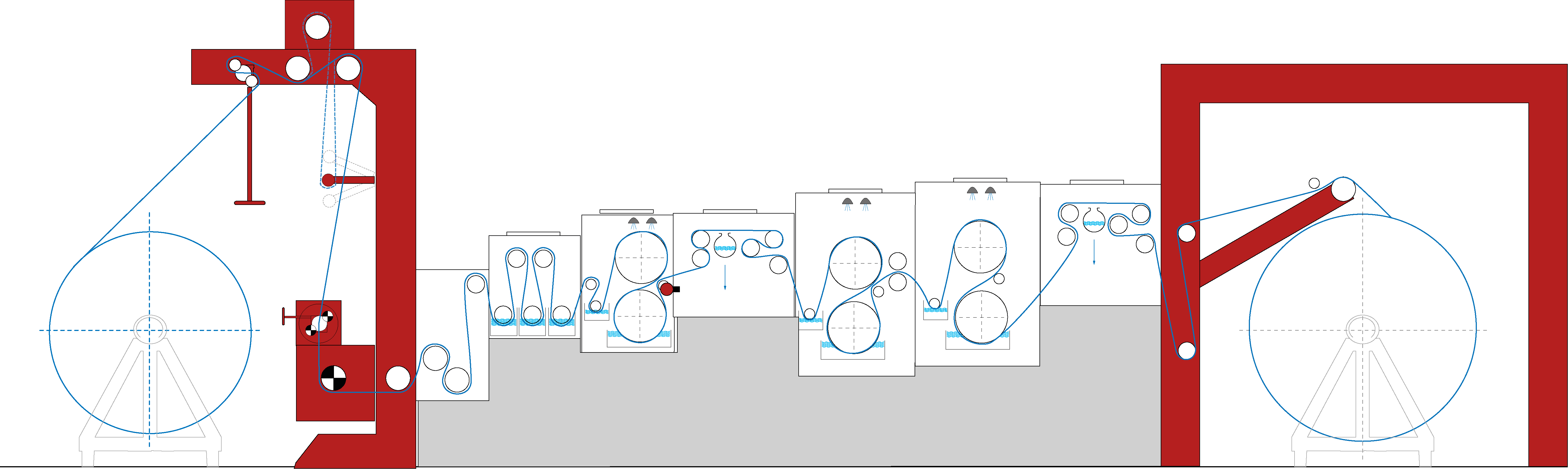

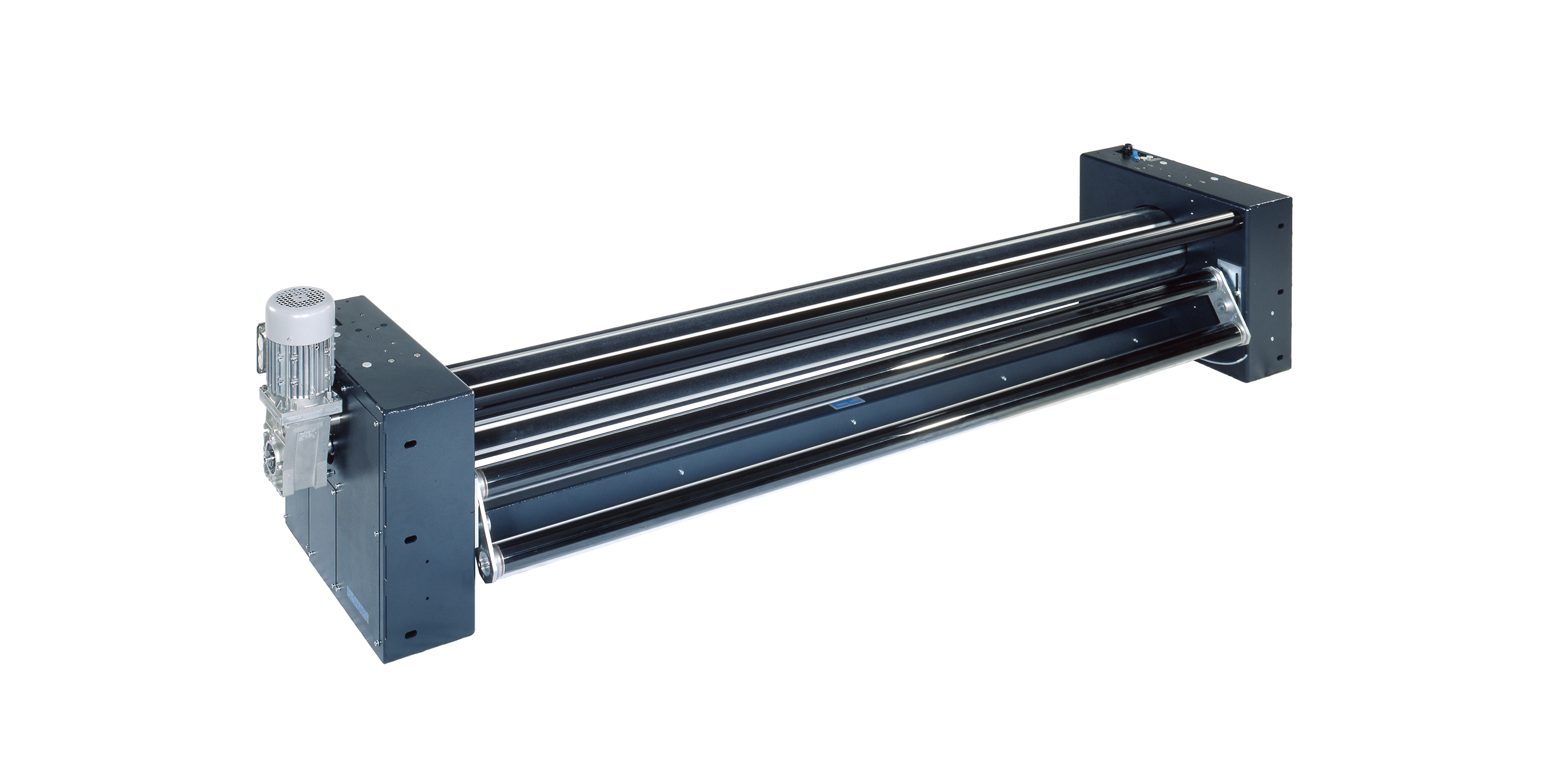

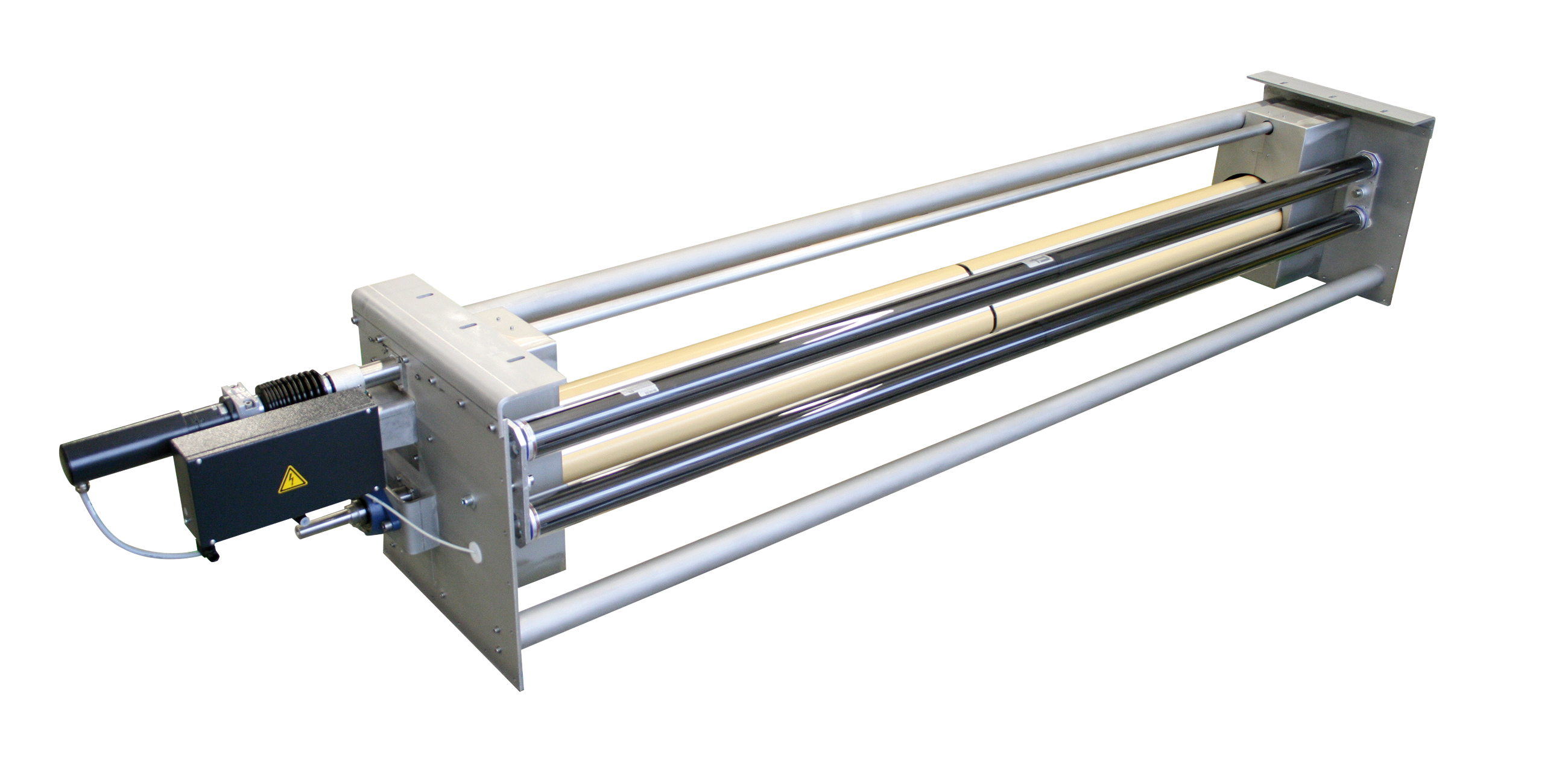

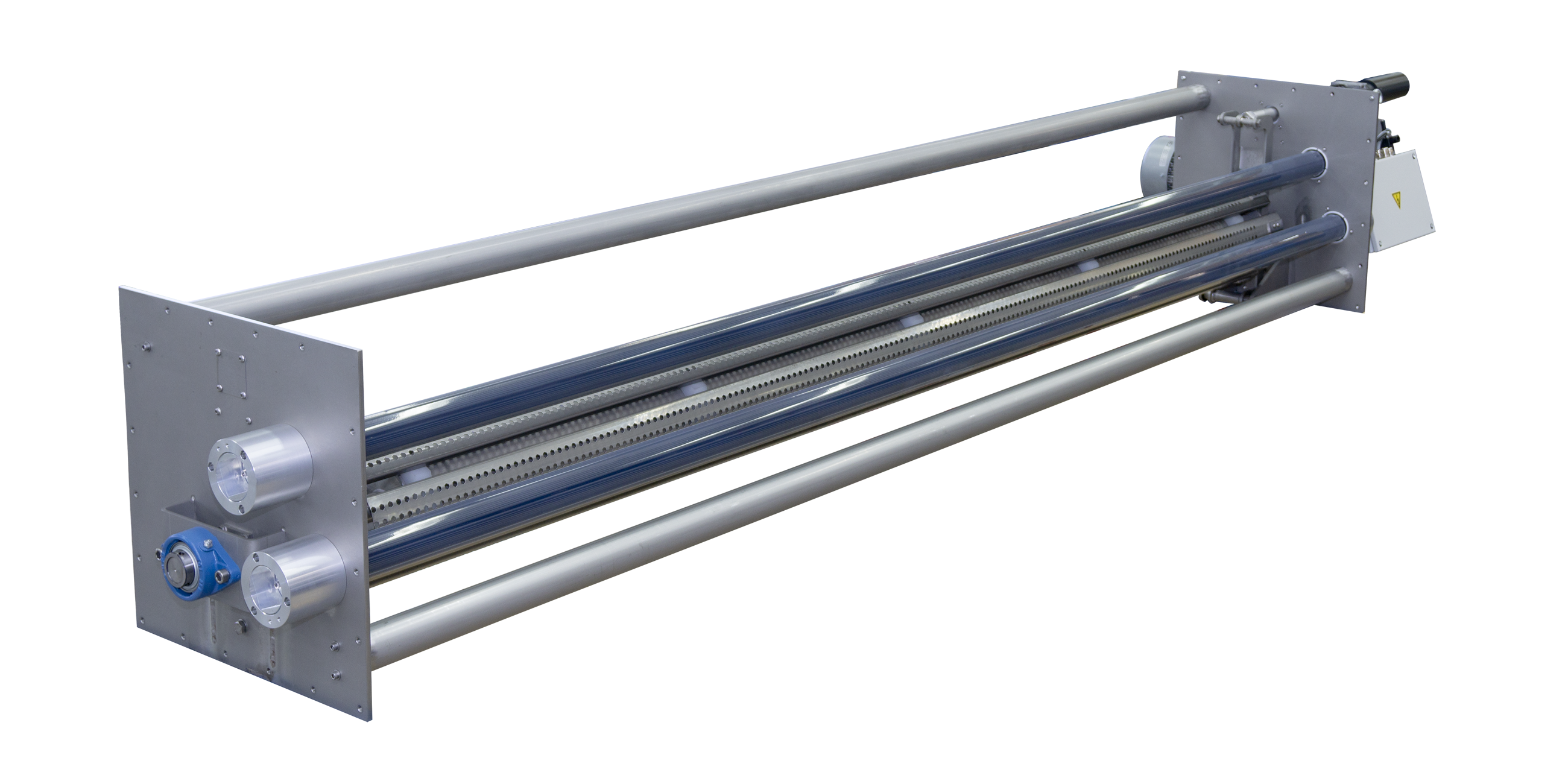

A fully spread web, guided by the center, is the prerequisite for an optimal washing or impregnation process in the washing machine. Systems are designed as roller vats or drum washing systems. In pretreatment as well as while washing out dyed or printed products, so-called steamers are used as "dwell tanks" to ensure the effectiveness of the processes or to optimize them. The increasing use of elasthane fibers places high requirements on the web guiding and web spreading also within washing or bleaching systems. The sensors used must be suitable for boiling temperatures. If the knitted fabric is to have high residual shrinkage values at the end of the process, continuous web tension control is an absolute must.